In case of a smoke or fire, the security system (if there is any) alarms the personnel, the fire extinguishing gets in operation, local firefighting department gets noticed etc. These actions are made to handle the abnormal situation, when the fire is already there. We can save more human lives, time and dramatically reduce cost if we concentrate more on early heat and overheat detection to prevent fire or explosion.

LICO provides the right solution with a wide range of custom made, certified heat detector units and systems concentrating on the fire prevention.

The higher the normal operation temperature is, passive fire detection products come more and more in the focus.

HDL products are almost every time custom made, bespoken with the customer and/or with the local system integrator. We cover a wide range of industrial use, like: engine rooms, transformer stations, wind generators, saunas, kitchens and also hazardous applications: painting room, gas turbines, off-shore platforms, oil refineries, nuclear power plants and many more.

ATEX, EN 54-5, CE and ISO 9001 certificates ensure the highest level of technical solutions.

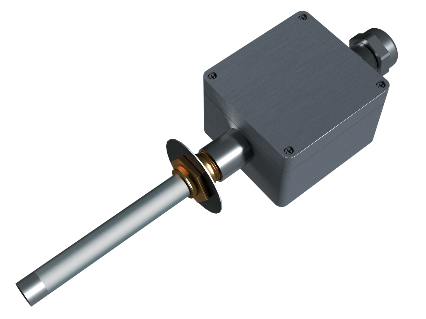

Our HDL heat- and overheat detectors are based on bimetallic, heat detector switches, free of electronics, to provide the best reliability in high temperature applications, also during harsh environmental conditions. Simplicity goes through in product family to provide easy installation and a very cost effective maintenance. Various alarm temperature settings are available from 140°F(60°C) until even 950°F(510°C) in N/O or N/C potential free contacts, which makes fast system integration in practically every already existing or new systems.

The sensors in the HDL units are designed with rate compensation. This function provides a unique advantage over both fixed temperature and rate-of-rise types of detectors. They accurately sense the surrounding air temperature regardless of the fire growth rate. Fixed temperature detectors must be completely heated to alarm temperature and therefore a lag in response time may occur with a fast rate of fire.

Rate-of-rise devices, on the other hand, are triggered by the rate of increase in ambient temperature and are subject to false alarms caused by harmless, transient thermal gradients, such as the rush of warm air from process ovens.

For more information please visit